Construction materials are the building blocks of any structure, and their quality and durability directly impact the safety, functionality and longevity of a building. One such material is concrete. Concrete is a mixture comprising cement, aggregates and water. Depending on the construction requirement, the proportion of these ingredients can differ. In this article, you can get information on how to calculate M25 concrete ratio for 1 cubic metre area.

What is M25 Concrete Ratio for 1 Cubic Metre?

The M25 concrete ratio for 1 cubic metre refers to a specific mix design for concrete, where the components are combined in a particular proportion to achieve a desired strength for a 1 cubic metre space. In this case, the ratio is 1:1:2, which means that for every one part of cement, one part of sand and two parts of aggregates (such as crushed stones or gravel) are used.

Features of M25 Concrete Ratio Per 1 Cubic Metre

The following are the various features associated with M25 concrete ratio:

Strength and durability

The mix design of concrete, including the ratio of its components, significantly affects its strength and durability. The M25 concrete ratio ensures that the resulting concrete has a characteristic compressive strength of 25 megapascal (MPa) or newtons per square millimetre (N/mm²) after 28 days of curing. This strength is suitable for various structural applications and ensures the longevity and stability of the construction.

Structural Integrity

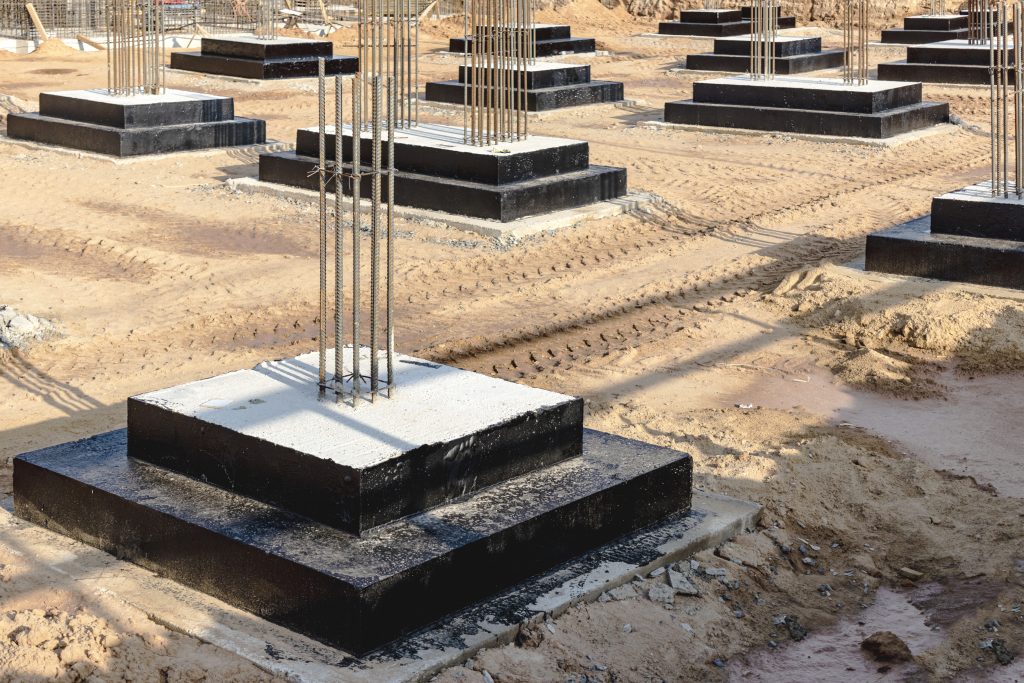

The M25 concrete ratio plays an important role in maintaining the structural integrity of the building or structure. By using the right proportions of cement, sand and aggregate, the concrete can withstand the intended loads, resist cracking and maintain its shape and form. This is especially important in heavy structures such as high-rising buildings, bridges and retaining walls.

Cost Effectiveness

Such concrete helps in optimising the use of raw materials, thereby reducing cost and wastage. By following the specified ratio, contractors and builders can accurately estimate the required quantities of cement, sand and aggregate, thus minimising excess material and unnecessary expenses.

Standardisation and Compliance

The M25 concrete ratio is based on the guidelines provided by the Indian Standard (IS) code. This code ensures uniformity and standardisation in the construction industry, hence promoting quality assurance and compliance with safety standards.

Efficient Construction Process

With the M25 concrete ratio, construction projects can proceed smoothly and efficiently. Contractors and workers can follow a standardised mix design, facilitating easier batching and mixing of materials on-site. This streamlines the construction process and helps meet project deadlines as well.

How To Calculate M25 Concrete Mix Ratio for 1 Cubic Metre Block?

Here’s a guideline on how you can calculate M25 concrete mix:

1. Calculate the target strength

The target average strength (f’ck) can be determined with the following formula:

f’ck= fck + 1.65s

Where,

- f’ck = average target compressive strength at 28 days.

- fck = characteristic compressive strength at 28 days.

- s = Standard deviation

- 1.65 = statistical value depending on the accepted proportion of low results and the number of tests.

2. Select the water-cement ratio

Different types of cementitious material and aggregates can produce concretes with different compressive strengths even when the the same ratio of water and cement is used. The details of the required water-cement ratio are stated in Table 5 of IS 456:200.

3. Select the water content

Aggregates of different size, shape and texture, cement and other supplementary cementitious material type and content, admixtures and overall environmental conditions impact the water content of concrete. Preference is to be given to potable water.

4. Calculate the cement content

Cement content can be calculated from the water quantity per unit volume of concrete and the water-cement ratio. The maximum cement recommendation is stated in IS 456:2000.

5. Calculate the aggregate content

Typically, both coarse and fine aggregates may be used in a concrete mixture, in varying proportions. For most construction work, a 20 mm aggregate is suitable. The proportions for a nominal mix concrete is specified in IS 456:2000.

6. Determine the water content and fine-to-aggregate ratio

To achieve the desired workability, mixing water per unit volume of concrete and the ratio of fine aggregate (sand) to total aggregate by absolute volume are to be estimated.

Explore a wide range of concrete cement with JK cement and unlock the potential of your dream home.

FAQs

What is the purpose of calculating the M25 concrete ratio?

The purpose of calculating the M25 concrete ratio is to determine the proportion of cement, sand and aggregate needed for a specific concrete strength.

What are the primary components used in the M25 concrete mix?

The primary components of M25 concrete mix are cement, aggregates and water.

How can I ensure the quality of M25 concrete for my construction project?

The quality of M25 concrete mix ultimately depends on the raw materials. Ensure you use good quality cement, the right aggregate size per the construction needs and potable water.