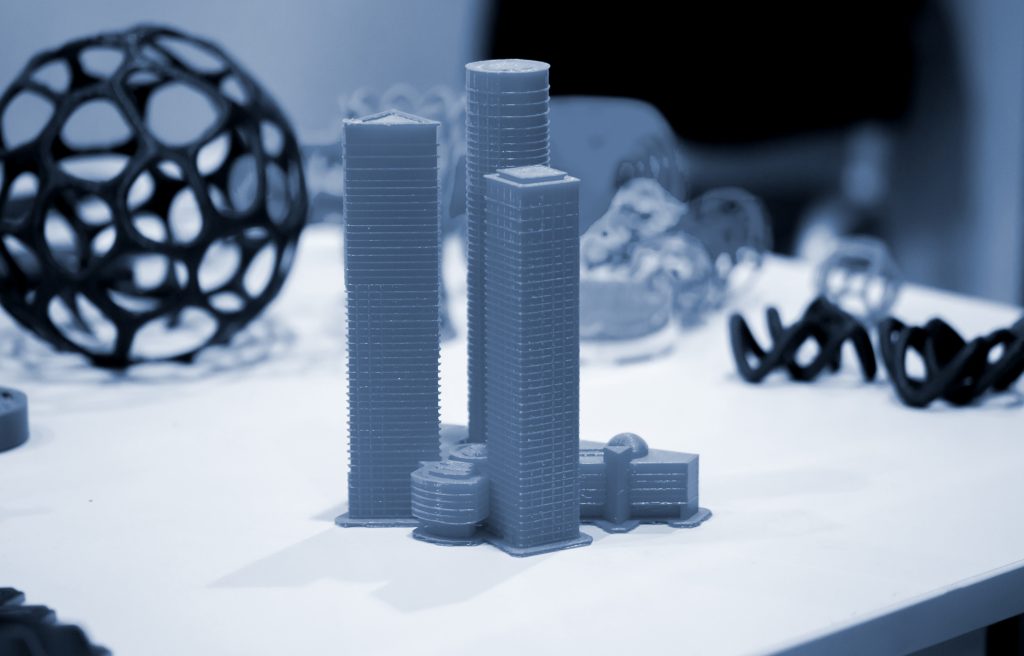

Construction practices continue to evolve for improved efficiency and sustainability. 3D printing is a tool that can redefine the way of building new infrastructures. The potential of 3D printing in construction is immense. It continues to revolutionise the industry by offering faster construction times, design innovation, and the promise of more sustainable building practices. Let us take a closer look at 3D printing in construction, its benefits, and opportunities for the future.

What Is 3D Printing In Construction?

3D printing, also known as additive manufacturing, is an innovative process of creating three-dimensional objects from Computer-Aided Design (CAD) models. It operates on a simple concept called layer-by-layer construction. 3D printing adds material in successive layers to build an object. This process begins with a digital 3D model designed using specialised CAD software or obtained through 3D scanning technologies. The model is then sliced into numerous thin horizontal layers to create a digital blueprint. These layers guide the 3D printer as it deposits material, typically plastic, concrete, metal, or other composite materials by following the precise instructions from the digital design.

How is 3D Printing Executed in Construction?

The process involves the use of large-scale 3D printers equipped with specialised nozzles or extrusion systems. These systems are designed to deposit construction-grade materials layer by layer to build entire structures. The construction-grade materials employed in 3D printing can vary and may include concrete, mortar, or other composite mixtures optimised for building durability. As the 3D printer begins its work, the nozzle moves along predefined paths depositing the construction material layer by layer. The layering process continues until the entire structure is complete. 3D printing in construction can create intricate architectural designs and customised structures with efficiency.

Benefits Of 3D Printing in Construction Industry

The adoption of 3D printing in construction offers a multitude of advantages that can redefine the industry’s approach to building:

Speed and efficiency:

3D printing accelerates the construction process significantly. The ability to fabricate complex structures in a fraction of the time compared to conventional methods reduces project timelines.

Cost savings:

By optimising material usage and minimising waste, 3D printing in construction slashes material costs. Moreover, the streamlined process can reduce labour expenses and overall construction expenditures.

Design flexibility and customisation:

3D printing allows architects and builders to explore intricate designs and tailored structures that were once challenging or impossible to create.

Sustainability:

With a focus on using materials more efficiently and producing less waste, 3D printing aligns with sustainability goals. Some methods even utilise eco-friendly materials, further reducing the environmental impact of construction.

Enhanced safety:

Automating certain construction processes through 3D printing reduces on-site labour requirements, potentially minimising worker exposure to hazardous conditions.

Remote construction:

The ability to transport 3D printers to remote locations facilitates construction in challenging or disaster-stricken areas, providing quick and efficient shelter solutions.

Structural strength and durability:

Innovative construction-grade materials used in 3D printing can be optimised for strength, durability, and resilience, resulting in robust structures built to withstand diverse environmental conditions.

Opportunities And Challenges For 3D Printing in Construction

With the rising utility of 3D printing in construction, global markets have the potential to boom substantially. However, with numerous opportunities, the industry needs to overcome some challenges to provide better solutions. Let us have a closer look:

Opportunities:

Customisation and innovation:

3D printing can create customised and complex designs. It enables you to build unique structures that were previously unattainable through traditional methods.

On-demand construction:

3D printing facilitates the possibility of on-site and on-demand construction, particularly in disaster-stricken areas or remote locations where immediate shelter solutions are crucial.

Sustainable construction practices:

3D printing allows the use of eco-friendly materials with reduced waste. It aligns with sustainability goals and offers an opportunity to minimise the environmental impact of construction.

Cost-effectiveness:

While initial investments might be substantial, long-term cost savings through reduced material wastage and labour expenses offer a significant opportunity to reduce construction costs.

Job creation and skill development:

As technology advances, it opens avenues for new job opportunities and skill development in the fields of design, engineering, and material sciences.

Challenges:

Scalability:

Handling the size of construction projects is a challenge for 3D printing systems. It requires technological advancements to cater to large-scale construction projects.

Cybersecurity:

Securing automated construction processes and safeguarding the 3D model data from potential hacking threats poses significant concerns.

Design and construction:

Integrating electrical and mechanical services into 3D printed structures remains a challenge, especially in remote locations.

Construction site suitability:

The uncontrolled and irregular environments of construction sites pose challenges for 3D printers, which demand controlled settings for optimal operation.

Lack of standards and regulations:

The absence of comprehensive regulations governing 3D printing in construction creates uncertainty and obstacles in ensuring standardised practices and safety.

Types Of 3D Printers

3D printing systems in construction come in varied types and are used depending on requirements. Here are some common types:

Concrete extrusion printers:

These printers specialise in extruding concrete mixtures layer by layer. They enable the construction of walls, floors, and even entire buildings. They utilise large nozzles to deposit concrete in precise patterns to gradually build the desired structure.

Robotic arm printers:

Equipped with robotic arms, these printers offer enhanced flexibility and manoeuvrability. They can navigate intricate paths depositing construction materials with precision. They are used to build more complex and customised designs.

Gantry systems:

These are used for large-scale construction projects. They feature a rigid framework that moves along a track depositing material to create structures efficiently over a large area.

At JK Cement, we offer superior-quality and reliable grey cement like Portland Pozzolana Cement (PPC) to help you craft enduring structures.

FAQs

How is 3D printing used in construction?

3D printing in construction involves using specialised printers to layer construction materials, like concrete or composite mixtures to build structures based on Computer Aided Designs (CAD).

What is 3D construction?

3D construction refers to the process of utilising additive manufacturing techniques to construct entire buildings or structural components using 3D printing technology.

How is 3D printing used in architecture?

In architecture, 3D printing enables the creation of detailed architectural models, complex designs, and even full-scale building components. It allows architects to create innovative structures.

How does 3D printing help the environment in construction?

3D printing aids environmental conservation by minimising material wastage, optimising resource utilisation, and offering the potential for sustainable material choices.

What are the benefits of 3D-printed construction?

The benefits of 3D printing include faster construction, cost efficiency through reduced waste, design flexibility for complex structures, and sustainability through optimised material usage.

What is the future of 3D printing in construction?

The future of 3D printing in construction has greater utility. With technological advancements, it will have expanded applications, increased efficiency, more advanced materials, and wider adoption of 3D printing in construction.

What are the risks of 3D printing in construction?

Risks include challenges in material quality and durability, regulatory uncertainties, cybersecurity threats, and the need for skilled professionals for seamless implementation.

Is construction using 3D printing technology sustainable?

3D printing in construction can be potentially sustainable as it offers reduced material wastage and the use of eco-friendly construction materials.