Quarry Meaning in Construction and Mining

Most people think construction starts when excavation begins at their plot. In reality, it starts far away – at a dusty stone quarry on the outskirts of a town or village.

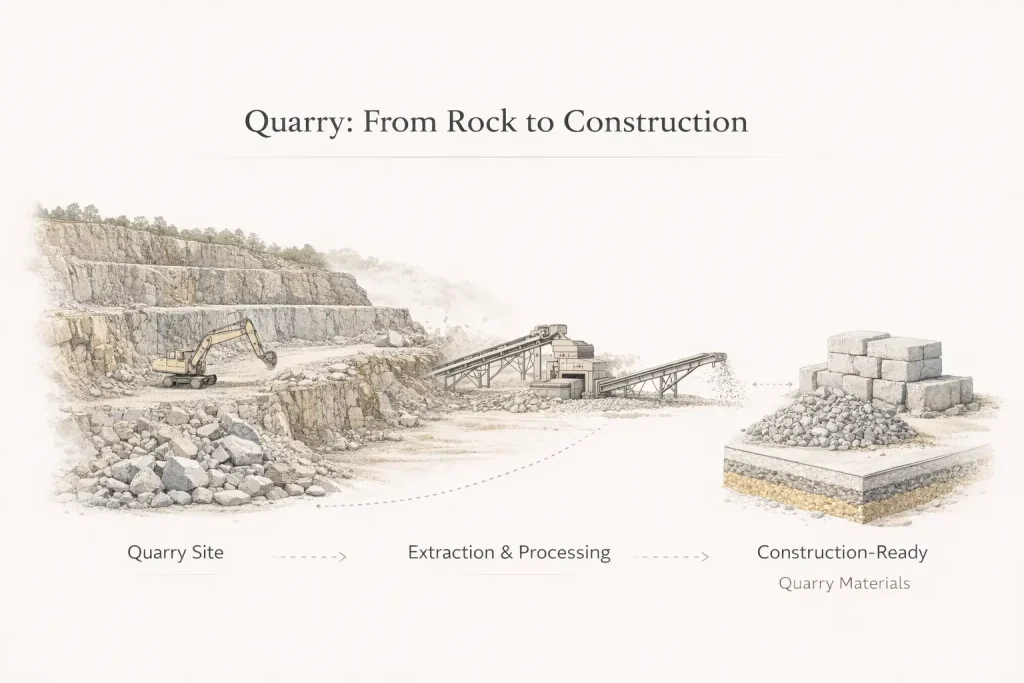

In plain terms, the meaning of quarry is: a site where stone is dug out of the ground for construction and industrial use.

From the gravel under your floor to the aggregates inside concrete, much of it starts at the quarry. Every slab, beam, and road depends on material pulled from the quarry. Without quarry mining, there’s no cement, no concrete, no aggregates, and no roads. Yet, quarries remain invisible to most homeowners.

Once you understand how quarry mining works, you realise construction doesn’t start on site – it starts much earlier.

This blog explains the meaning of quarry in construction and mining, how quarrying is done, and why it matters more than most people realise.

The Meaning of Quarry Explained

Quarrying is the process of extracting stone, rock, sand, or aggregates from the earth’s surface. Unlike deep mining, quarry mining usually happens in open pits.

A quarry is not a random hole in the ground. It’s a carefully planned site where layers of rock are removed step by step.

In construction terms:

- A stone quarry supplies raw material

- Quarry mining breaks down large rock masses

- Processed stone is sent to crushers and plants

If you’ve ever seen trucks loaded with blue metal or aggregates heading towards a city, they’ve come from the quarry.

How Quarry Mining Works on the Ground

Quarrying isn’t chaotic. It follows a method.

First, engineers study rock formation. Not all stones are useful. Once the right layer is identified, the quarry area is cleared and prepared.

Typical steps in quarry mining are:

- Removal of the topsoil

- Drilling of rock layers

- Blasting or cutting process

- Stones broken into manageable sizes

- Transportation of cut stones for crushing.

Each stage affects the quality of the final product. That’s why the meaning of quarry goes beyond digging – it’s about controlled extraction.

Methods of Quarrying

Different sites need different approaches. The method used depends on rock type, location, and safety.

1. Open-Pit Quarrying

This is the most common quarry mining method. It includes:

- Large pit excavated layer by layer

- Used for limestone, granite, basalt

- Common in road and building projects

- Most stone quarry operations in India use open-pit quarrying.

2. Terrace or Benching Method

Here, the quarry is cut into steps or benches.

- Improves safety.

- Allows controlled blasting.

- Makes material handling easier.

When you see a quarry that looks like a giant staircase, this is the method being used.

3. Channelling Method

Used mainly for dimension stones.

- Stone blocks cut cleanly

- Less blasting

- Used for granite and marble

This method preserves stone quality, which matters when blocks are used directly in construction.

4. Underground Quarrying

Used when open excavation isn’t practical.

- Common for high-value stones like marble or limestone

- Causes less surface disturbance

- Needs careful planning and skilled execution.

This method is slower and more expensive – used when surface quarrying isn’t an option.

Each method serves a purpose. That’s why understanding the meaning of quarry also means understanding how stone quality is controlled.

Difference Between Quarrying and Mining

People often confuse the two. The distinction is important because quarrying impacts construction quality directly.

- Mining usually goes deep underground.

Quarry mining stays closer to the surface. - Mining focuses on minerals like coal or metals.

A quarry focuses on building materials.

Importance of Quarrying in Construction

Without quarrying, modern construction would stop. Here’s why the quarry is critical:

- Supplies aggregates for concrete

- Provides raw material for cement production

- Enables road and infrastructure development

- Supports drainage and foundation systems

Every bag of cement needs limestone from a stone quarry, and every concrete slab needs aggregates sourced through quarry mining. JK Super Cement is known to manufacture cement with the best quality aggregates.

If quarry material is weak or inconsistent, buildings suffer. For example, poor-quality aggregates can reduce concrete strength. That’s why responsible sourcing and processing matter as much as mixing on-site.

Quarrying and Quality Control

Not all quarries are equal. A good quarry:

- Tests stone regularly

- Maintains consistent size and grading

- Follows environmental guidelines

A poorly managed quarry sends mixed or dusty material, which weakens concrete and increases cement consumption.

Understanding the meaning of quarry helps contractors and engineers ask the right questions instead of blindly accepting material.

Quarrying – Purpose Beyond Construction

Quarry mining doesn’t only serve buildings. Stone from quarries is used in:

- Railway ballast

- Landscaping

- Drainage systems

- Industrial flooring

Even decorative stones in gardens often come from a stone quarry, just processed differently.

Environmental Responsibility and Quarrying

Modern quarrying isn’t just about extraction. It’s about doing it responsibly so that the quarry isn’t detrimental to the landscape. This is done by:

- Restoring land after use.

- Controlling noise and dust.

- Managing water runoff.

A quarry may seem far removed from your home, but it’s deeply connected.

The real quarry meaning lies in being the foundation of construction – literally.

From cement to concrete, from roads to roofs, quarry mining supports it all. When you understand where materials come from, you build smarter, choose better, and demand quality.

Every strong structure begins at the quarry. Respect that starting point, and the rest of the construction falls into place.

FAQs

1. What is the meaning of quarry in construction?

The quarry refers to extracting stone and aggregates used in building and infrastructure work.

2. What is a stone quarry?

A stone quarry is a site where rock is extracted for construction materials.

3. Is quarry mining harmful to the environment?

It can be, if unmanaged. Responsible quarry mining includes land restoration and dust control.

4. How are quarrying and mining different?

Quarrying is done on the surface level, while mining usually goes underground.

5. Why is quarrying important for cement?

The limestone that is extracted from quarrying is a key ingredient of cement.

6. Can quarry materials affect building strength?

Yes. Poor-quality stone can weaken concrete and foundations.

7. Are quarries permanent?

No. The quarry is usually restored or repurposed after material extraction is complete.